Syncro Group is gearing up for PLAST, a highly significant trade fair for the plastics industry, scheduled to take place at Fiera Milano from September 5th to 8th.

At Plast 2023, Syncro Group is set to showcase its latest PLANET-APPROVED products, which align with their ZERO WASTE MISSION. These products are designed to minimize industrial waste, energy consumption, and raw material usage, all while maintaining comprehensive control over overall output.

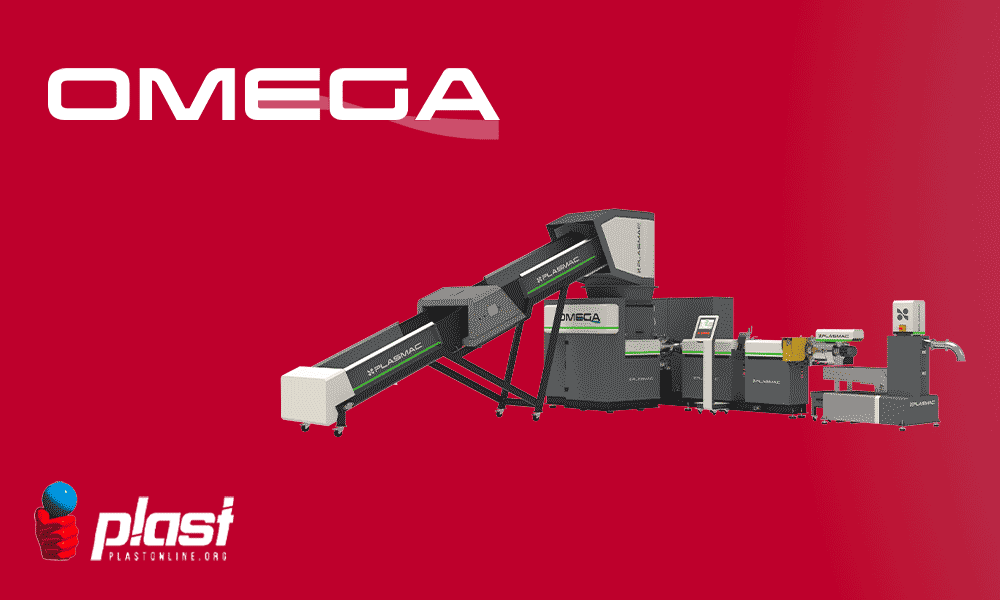

Among the highlights, PLASMAC, a leading player in in-line and out-line grinding and granulating systems for post-industrial waste, will be a prominent presence. The spotlight will be on mini ALPHA XS and OMEGA systems, both operational during the event.

Addressing the escalating costs of energy and raw materials, as well as the growing need for in-house recycling of post-production scrap, PLASMAC has developed the OMEGA series. With a capacity range from 120 to 250 kg/h, this solution caters to producers of various materials such as PE, PP, PC, PMMA, ABS, TPU, and TPE. It eliminates the need for prior size reduction and takes into account the hardness of generated waste.

The revolutionary OMEGA recycling extruder system, a PLASMAC creation, introduces a transformative approach to recycling. Integrating a compact shredder with Short Screw Technology (SST), this innovative system employs a dual-diameter ratio screw to efficiently process waste and produce top-notch recycled pellets. The operation is straightforward but impactful: waste enters the slow-rotating shredder through an elevator, roll feed, or trim basket, allowing diverse forms of scrap material to be fed in a single step. The screen design minimizes heat and dust, yielding high-quality pellets with fewer imperfections.

An added perk is the PLASMAC TYGER’S CAMERA, located within the hopper and connected to the user-friendly HMI system. It enables easy operational control, storing multiple receipts based on the plant’s materials portfolio.

Energy efficiency stands as a defining feature of the OMEGA system, offering the highest output per kilowatt of installed power in the market. This translates to reduced running costs and a speedy return on investment, with potential paybacks in as little as six months. The technology eliminates the need for cooling water in the rotor or transfer system, reducing both maintenance and costs while improving profitability. In addition, the OMEGA system boasts a compact footprint, consuming minimal floor space and freeing up room for other applications.

Complementing the core system, OMEGA offers a range of ancillaries to enhance its performance. These include air or water-cooled palletizers, trim baskets for inline trims, reel feeds for off-spec or scrap reels, elevators, metal detectors for various scrap types, screen changers for offline products, vacuum degassing stations for printed or hydroscopic materials, pellet detection system to identify issues in the pelletizer.

Notably, PLASMAC has introduced a gravimetric system for real-time output calculation, enabling automatic adjustments to ensure optimal efficiency by aligning production with consumption.

Each OMEGA unit features remote connection capability, adhering to Industry 4.0 standards and linking to PLASMAC HUB and TYGER CLOUD platforms. This groundbreaking innovation empowers users to remotely monitor and manage the production process, from purchasing spare parts to accessing remote assistance services.

In summary, the OMEGA recycling shredder extruder system offers a comprehensive and efficient solution for transforming waste materials into high-quality pellets. Its distinctive features and accompanying systems make it a cost-effective and profitable choice for recycling industry businesses.

Syncro Group unites a constellation of advantages and expertise from different specialists in the field, facilitated by the synergy between companies such as SYNCRO, PLASMAC, PLANTECH-CST, ACELABS, EUR.EX.MA., and SB DRY.